| Info | ||

|---|---|---|

| ||

This page is a work in progress. This info box will be removed when it's complete. |

Key Performance Indicators (KPIs) are high level measurements of the status of the supply chain. KPIs are sourced from underlying indicators and transactional information within the supply chain. This document defines common KPIs (i.e. DISC Indicators) that provide high level measurement as well as a minimum set of metrics that collect information from the point of service transaction.

| Table of Contents |

|---|

Key Performance Indicators

Enter here

Metrics

(Source Data) Requisition Fields for Metrics

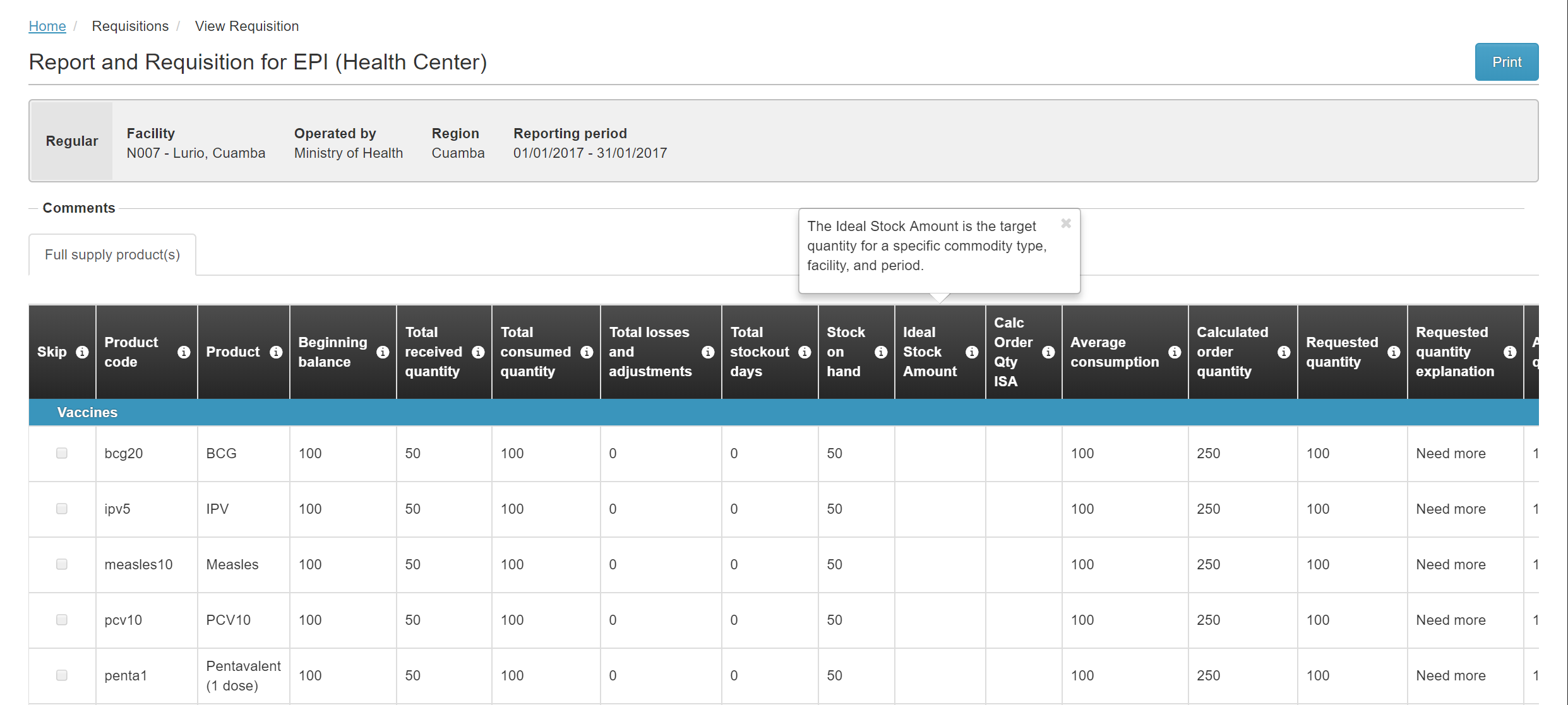

The view above shows the fields from the requisition that need to be mapped to the metrics. This work has already been done for the OpenLMIS reporting stack.

- Program - (Displayed as "EPI" in title) is a grouping of orderables, configuration and facility network associated with a specific funding source

- Facility - Defines the location the requisition was created from

- Reporting Period - The period of the requisition (usually, monthly or quarterly)

- Product - Each row in the requisition represents a product with a Product Code and Product name

- Beginning balance - Based on the Stock On Hand from the previous period quantified in dispensing units

- Total received quantity - Total quantity received in the reporting period quantified in dispensing units

- Total consumed quantity - Quantity dispensed/consumed in the reporting period quantified in dispensing units

- Total losses and adjustments - All kind of losses/adjustments made at the facility

- Total stockout days - Total number of days facility was out of stock

- Stock on hand - Current physical count of stock on hand quantified in dispensing units

Sample Requisition Screenshot from OpenLMIS:

Metrics (from DHIS2 Metric Scope and Definition Page)

Below is the list of indicators that our DHIS2 integration will support. Each one is calculated per product, reporting period, facility, and program.

Stock Status

This metric evaluates the status of stock for each line item. Four values are returned Stockout, Understocked, Adequately Stocked and Overstocked. Below describes how these metrics are calculated against the core Requisition source data:

- Stockout: stockOnHand = 0, totalStockoutDays > 0, beginningBalance = 0, or if maxPeriodsOfStock = 0

- Understocked: 0 < maxPeriodsOfStock < 3

- Adequately Stocked: 3 <= maxPeriodsIOfStock <= 6

- Overstocked: maxPeriodsOfStock > 6

Received Quantities

The amount from the totalReceivedQuantity field on the requisition line item for that product, reporting period, and facility.

Consumed Quantities

The amount from the totalConsumedQuantity field on the requisition line item for that product, reporting period, and facility.

Total Stockout Days

The total number of days in the totalStockoutDays field on the requisition line item for that product, reporting period, and facility.